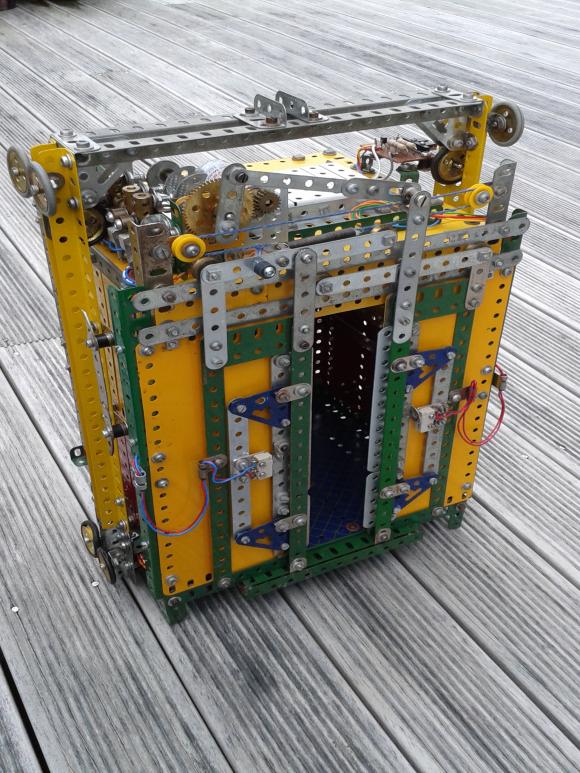

The model began with the construction of the car. I wanted to incorporate working safety edges and the doors had to be large enough to work reliably without jamming. A Meccparts motor operates one door through a crank and linkage, and the other door tracks it using a string and pulley arrangement. Early on I found that the doors had to be hung on widely spaced rollers or else, being long and narrow, they tended to tilt and jam. My answer was to use a track for each door, one above the other, with the rollers interleaved. The whole assembly had to be kept as thin as possible to avoid later problems with clearances in the lift shaft.

The shaft for the door operator crank also carries three “snail” cams. These operate micro switches, which detect the “doors fully open” and “doors closed” positions, plus a third which disables the safety edges when the doors are almost shut (otherwise when they hit together, you would have endless door re-opens…)

The lift car has internal details such as a blue and gold plated floor, LED lighting, and a handrail. Other features are the guide wheels on the car frame, a long cam on one side for operating the lift shaft-mounted limit switches at the extremes of travel, and on the other side, an electronic photo interrupter which produces pulses from cardboard vanes set up in the lift shaft. These pulses are used by the controller to count the floors, and to stop the car level with the floor.

Optimized for Broadband (Login for Dialup Optimization)

Home

Home Contact Us

Contact Us Newsletters

Newsletters